At Sheldon Precision, we’re aware that careful planning acts as an essential cog in the machining process. It can often be on par with the machining itself! Even a minor disruption in scheduling, materials, or capacity forecasting can have a knock-on effect across production.

That’s why accurate forecasting has become a core part of how we operate at Sheldon Precision, ensuring every order runs smoothly from quotation to delivery.

Over the past year, we’ve invested in new MRP and planning software that has completely transformed our scheduling process. The result? Improved efficiency, reduced downtime, and a consistently strong on-time delivery record.

Accurate Forecasting, Real Results

Our forecasting improvements have already produced measurable gains.

For example, in September 2025, we achieved 95.5% on-time deliveries, continuing a year-long trend of outstanding delivery performance. Earlier in the year, in May 2025, 61.1% of jobs were completed early, 27.8% on-time, and only 11.1% were late. This data clearly indicates that our proactive planning is helping us stay ahead of schedule.

We continue to review our delivery performance each month, using the data to refine our approach and maintain consistency. By working closely with suppliers and carriers alike, we certify that material deliveries and logistics align precisely with our production schedules. This attention to planning allows us to maintain reliability across hundreds of active customer projects.

Precision in Numbers

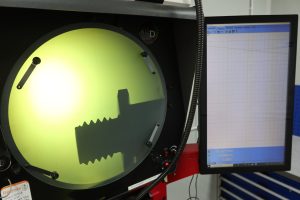

Behind these delivery results is a production capability built on both scale and precision.

Earlier this year, we achieved a notable milestone by producing more than a quarter of a million precision-engineered parts within a single year.

In February, our team machined over 60,000 individual components, maintaining an average tolerance between 50–100 microns — thinner than a human hair! Achieving that level of accuracy at volume requires more than advanced machinery; it depends on the ability to forecast demand, allocate capacity, and plan tooling well ahead of production.

Technology That Powers Precision

The introduction of our new MRP and planning/scheduling system has been a genuine game-changer.

It gives our team real-time visibility across materials, capacity, and workflow, allowing us to model “what-if” scenarios, anticipate bottlenecks, and distribute workloads efficiently across our Citizen and Miyano CNC machines.

This level of control means we can move from reactive to proactive planning. Responding to problems after they arise is inefficient; therefore, we aim to predict them, adjust workloads early, and keep production flowing. This is where precision in the planning stage can directly translate into shorter lead times, improved machine utilisation, and greater customer confidence.

Managing Order Scheduling Challenges in Precision Engineering

Balancing Different Job Types

Most precision workshops, including ours, manage a constant mix of repeat production and bespoke one-off parts. The challenge lies in forecasting workloads that keep machines busy without pushing capacity too far.

Material Availability and Lead Times

While global supply chains remain unpredictable, due diligence is required to allow buffer time in each project. Likewise, keeping a close eye on supplier reliability ranks just a highly in the priority list. These careful considerations help us to protect schedules from delays outside our control.

Downtime and Preventative Maintenance

Even the most well-planned production schedule can swiftly fall to its knees without proactive maintenance. That’s why we rely on predictive upkeep and backup planning to keep every spindle turning.

People and Programming Resources

Machining time isn’t the only factor to plan for. Skilled programmers and operators need the same level of coordination, too. Matching expertise to the right job keeps quality and throughput consistent.

Responding to Customer Demands

Priorities can change overnight. We maintain enough flexibility in our forecasting systems to respond quickly to urgent orders or specification changes without disrupting ongoing work.

In short, forecasting in precision manufacturing is as much about data discipline as it is about technology. Systems only work if the data feeding them is accurate, clean, and continually updated.

From Data to Delivery: Turning Forecasting into Performance

At Sheldon Precision, forecasting has become the link between production planning and customer service.

By accurately predicting workloads, we can quote realistic lead times, schedule confidently, and avoid the kind of last-minute disruptions that affect consistency.

Our data-driven approach means that every area of our business sings from the same hymn sheet. This transparency ensures that materials, machines, and the workforce are always neatly aligned. The result is not only operational efficiency but also greater peace of mind for our customers, who know their orders will arrive exactly when promised.

The Industry’s Move Toward Predictive Planning

Across the precision engineering sector, the way orders are planned and scheduled is changing fast. More workshops are now using data from connected machines and smart software to anticipate demand, manage capacity, and react quickly to changes in workload.

Modern MRP platforms can now track live shop-floor data, analyse machine performance, and automatically adjust schedules based on real-time conditions. The next stage for many companies (including us) is to integrate these capabilities into a complete predictive planning model that learns from past performance to improve future accuracy.

Forecasting is no longer just about anticipating demand; it’s about adapting to it in real time.

Working on Continuous, Data-Driven Improvement

We treat forecasting as a living process that develops with every production cycle. Each month’s performance data assists us in refining not only how we plan but also how we schedule and deliver. By comparing forecasted versus actual performance, we identify opportunities to reduce variance, improve machine utilisation, and strengthen supply chain resilience.

This commitment to continuous improvement extends beyond our systems. It’s part of what we instil in our culture at Sheldon Precision; one built on teamwork, accountability, and a tireless focus on quality. Whether we’re machining a prototype or carrying out a large production run, accurate order scheduling remains the foundation of our success.

Planning for Tomorrow’s Demands

Our commitment to order scheduling and planning revolves around delivering precision, trust and reliability across every order we produce.

By combining data-driven scheduling with decades of engineering expertise, we’re proving that excellent manufacturing doesn’t just happen on the machines. Instead, it begins with how you plan them.

Our precise order scheduling supports us as we strive to keep our promise of sharp delivery and relentless quality. After all, precision isn’t just measured in microns, it’s measured in performance.