Walk into a modern machine shop today, and you will see far more than lathes, mills and cutting tools. While precision engineering remains a craft built on skill, experience and attention to detail, the environment around it has changed dramatically over the past two decades.

Technology now underpins how work is planned, produced, measured and delivered. From real-time data collection on the shop floor to CAD/CAM programming and motorised material handling, the modern machine shop is increasingly digital. This shift is not intended to replace people, but to support them.

At Sheldon Precision, technology is viewed as an enabler. It is a way to improve consistency, visibility and efficiency while maintaining the flexibility and quality that customers expect from a specialist UK precision engineering partner.

Shop Floor Data Collection Points

One of the most significant developments in modern machining environments is the ability to capture accurate, real-time data directly from the shop floor.

Operators no longer rely solely on handwritten job cards or end-of-shift updates. Digital data collection points allow information such as job status, machine utilisation, cycle times, downtime and scrap rates to be logged as work happens. This creates a far clearer picture of what is actually going on across the shop at any given moment.

Over time, this data becomes invaluable. Patterns emerge, bottlenecks can be identified, and informed decisions can be made around scheduling, maintenance and investment. Crucially, it also removes ambiguity, as production conversations are based on facts rather than assumptions.

Digital Dashboards

Collecting data is only helpful if it can be understood and acted upon. Digital dashboards transform raw information into clear, accessible insights for both management and production teams.

Well-designed dashboards show live job progress, machine availability, delivery performance and workload distribution across departments. This visibility allows teams to respond quickly to changes, whether that means reallocating work, adjusting priorities or communicating proactively with customers.

In a fast-moving machine shop, dashboards help keep everyone aligned. They support more effective daily planning meetings, reduce surprises, and ensure performance is measured consistently rather than anecdotally.

Planning Software

Modern planning software has largely replaced manual scheduling boards and spreadsheets. Advanced planning systems allow machine shops to sequence work based on capacity, material availability, lead times and delivery commitments.

This is particularly important in high-mix, low-volume environments where priorities can change quickly. Planning software makes it easier to reschedule without losing control, ensuring that urgent work can be accommodated without disrupting existing commitments.

When planning is accurate and visible, lead times become more reliable, and reliability is often just as important to customers as speed.

ERP Software

Enterprise Resource Planning (ERP) systems form the foundation of many modern machine shops. Rather than information being stored in isolated systems, ERP software brings quoting, purchasing, stock control, production, quality and invoicing together in one place.

For engineering businesses, this integration is essential. Material traceability, batch control and revision management all depend on accurate, connected data. ERP systems also support continuous improvement by allowing historical performance to be analysed across jobs, customers and processes.

Used correctly, ERP software reduces duplication, improves accuracy and ensures that everyone is working from the same information, from the shop floor through to finance.

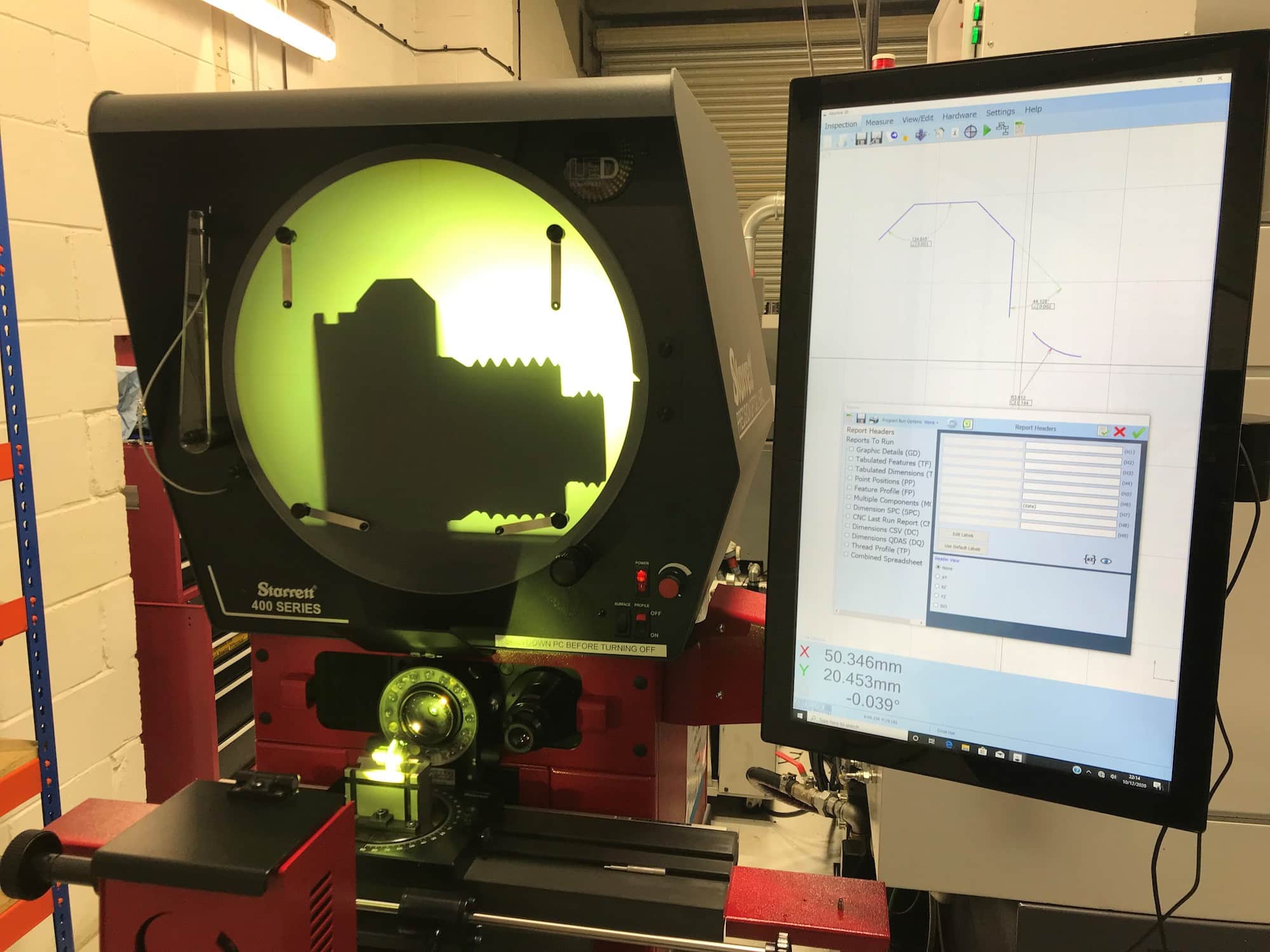

Digital Measuring Instruments

Precision engineering demands precision measurement, and digital measuring instruments have become standard in modern machine shops.

Digital micrometres, callipers, height gauges and bore gauges provide faster, more repeatable readings and reduce the risk of interpretation errors. Many instruments can also interface directly with inspection systems, allowing measurement data to be logged automatically.

This not only improves efficiency but also strengthens quality control and traceability. Recorded measurement data supports internal quality processes and provides customers with confidence that parts have been inspected and verified against specification.

While email may seem unremarkable compared to more advanced systems, it remains a vital communication tool in modern machining operations.

Quotations, drawings, revisions, approvals and delivery confirmations are all managed electronically, creating clear audit trails and reducing the risk of miscommunication. Email also enables faster collaboration with customers, suppliers and subcontractors, which is imperative in complex or time-sensitive projects.

The key is discipline. Structured communication, controlled document versions and clear ownership ensure that email supports operations rather than complicates them.

CAD

Computer-Aided Design (CAD) software has transformed how components are developed and refined before they ever reach the machine.

Modern CAD systems allow engineers to visualise complex geometries, identify potential issues early, and make rapid design changes without costly rework. For customers, this often means faster feedback during the design phase and greater confidence that parts will be manufacturable.

CAD also supports collaboration between design, programming and production, ensuring that intent is clearly understood before machining begins.

CAD/CAM

The integration of CAD with Computer-Aided Manufacturing (CAM) has been one of the most impactful technological shifts in precision machining.

CAM software converts digital models into optimised toolpaths, accounting for machine capabilities, tooling, materials and tolerances. This improves consistency, reduces programming time and allows complex components to be produced efficiently and repeatably.

Simulation features further reduce risk by identifying collisions or inefficiencies before parts reach the machine, saving both time and material.

Communication Platforms and Messaging

In addition to formal systems, modern machine shops increasingly use instant messaging platforms to support day-to-day communication.

Quick questions, image sharing and rapid updates between teams can significantly reduce delays, particularly when issues arise during production. Used sensibly and professionally, these tools complement formal communication channels rather than replace them.

The emphasis remains on clarity, accountability and maintaining accurate records where required.

Computer-Driven Machines

At the heart of the modern machine shop are CNC machines, which are computer-controlled systems that deliver exceptional accuracy and repeatability.

Today’s machines offer advanced control features, multi-axis capability, probing systems and connectivity that allow them to integrate seamlessly with planning and monitoring software. This enables higher levels of consistency, reduced setup times and improved utilisation.

Significantly, technology enriches operator skill rather than diminishing it. Experienced machinists remain essential for decision-making, problem-solving and maintaining quality standards.

Automation: Bar Feeders and Conveyors

Automation is increasingly used to support productivity and consistency, particularly in batch and repeat work.

Bar feeders allow lathes to run for extended periods with minimal manual intervention, while conveyors and part handling systems reduce manual handling and improve flow between processes. Automation improves efficiency, supports lights-out machining where appropriate, and frees skilled operators to focus on higher-value tasks.

The most effective automation is carefully targeted and designed to support existing processes rather than impose unnecessary complexity.

Technology as an Enabler, not a Replacement

Technology in a modern machine shop is not about removing people from the process. It is about giving skilled engineers better tools, clearer information and greater control over quality and delivery.

When systems are implemented thoughtfully, they improve visibility, reduce waste and strengthen customer confidence, while preserving the craftsmanship and expertise that define high-quality precision engineering.

For businesses like Sheldon Precision, the goal is balance. Modern digital capabilities are combined with decades of machining expertise to deliver reliable, high-precision components in an increasingly demanding manufacturing landscape.